square tube bending service

How to Make the Perfect Steel Square Tube Bending Part

CNC TUBE BENDING SERVICES

1/7/20252 min read

Creating a precise and high-quality steel square tube bending part requires careful planning, appropriate equipment, and a well-defined process.

Here are the key steps to achieve the best results:

1. Choose the Right Material

1.1. Material Grade: Select a steel grade suitable for bending, such as mild steel, stainless steel, or other steel alloys with good ductility.

1.2. Wall Thickness: Ensure the tube has a sufficient wall thickness to prevent collapsing or wrinkling during bending.

1.3. Surface Finish: Consider surface treatments like galvanization or powder coating if the part requires corrosion resistance.

2. Design Considerations

2.1. Bend Radius: Follow the "minimum bend radius" rule, typically 2-3 times the tube's diameter, to avoid cracking or deforming.

2.2. Allow for Springback: Steel tends to "spring back" after bending, so calculate the over-bend angle to compensate.

2.3. Support Holes or Inserts: If the part includes holes, design them away from bend areas to prevent distortion.

3. Select the Appropriate Bending Method

3.1.Rotary Draw Bending (Recommended for precision): This method ensures high accuracy and minimal deformation, especially for tight radii.

3.2. Mandrel Bending: Use a mandrel inside the tube to maintain the cross-sectional shape and prevent wrinkling.

3.3. Roll Bending: Ideal for creating large-radius bends.

3.4. Compression Bending: A cost-effective method for simple bends but less precise for tight radii.

4. Use Proper Tooling

4.1. Bending Dies: Match the die radius to the tube dimensions for consistent bending.

4.2. Clamping Tools: Secure the tube to prevent slippage during the process.

4.3. Mandrels and Wipers: For tight bends, use a mandrel and wiper die to support the tube and reduce wrinkling.

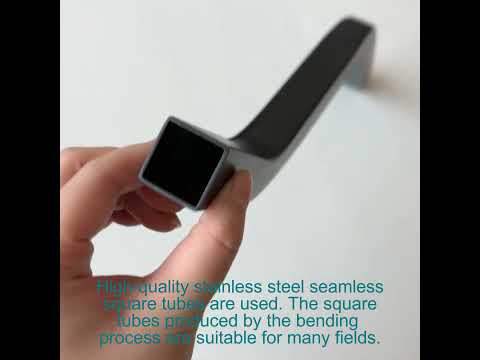

Steel Square Tube Bending Part

5. Optimize the Process

5.1. Heat Treatment: For thicker or harder steel, preheating the tube can reduce cracking and improve ductility.

5.2. Lubrication: Apply a suitable lubricant to reduce friction and prevent damage to the tube surface.

5.3. Slow and Controlled Bending: Avoid fast bending speeds, which can cause kinks or flattening.

6. Perform Quality Checks

6.1. Dimensional Accuracy: Use calipers and templates to ensure the bend angles and radii meet design specifications.

6.2. Surface Finish: Inspect for cracks, wrinkles, or scratches on the bend areas.

6.3. Structural Integrity: Perform pressure or load testing if the part is subject to high stress in its application.

7. Post-Processing

7.1.Deburring and Cleaning: Remove any sharp edges or debris from the bending process.

7.2. Welding or Assembly: If the part is part of a larger assembly, ensure proper alignment during welding or joining.

7.3. Coating or Plating: Apply finishes like powder coating, galvanizing, or painting for protection and aesthetics.

8. Extra Tips for Perfect Results

8.1. Work with skilled operators who have experience in tube bending.

8.2. Use advanced CNC bending machines for precise and repeatable results.

8.3. Consider outsourcing to a professional tube bending service if the part requires high complexity or tight tolerances.

By following these steps, you can produce high-quality steel square tube bending parts that meet your design and functional requirements. You can also contact us to get more practical support and solutions.

Follow Us

Contact

© 2024. All rights reserved.

Privary Policy

Refund Policy