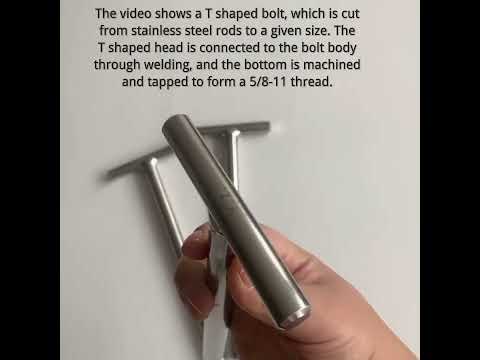

Stainless Steel T-Shaped Bolts

How do we save costs for manufacturing T-shapt bolts?

11/28/2024

Machiningfabtech is trying to find the best solutions for customers to save cost, we hereby share the experience of making T bolts in small order quantity.

When it comes to saving the cost of T bolts in small quantities, the process of TIG welding stands out for its precision, high strength, and durability. Designed with advanced "laser marking technology", these bolts not only meet functional requirements but also provide branding opportunities. With stainless steel as the primary material, these T-shaped bolts are perfect for industries requiring strength and corrosion resistance.

Features of Stainless Steel TIG Welding Bolts

1. Material Durability

Made from premium stainless steel, these bolts are resistant to rust, oxidation, and extreme temperatures, ensuring long-lasting performance.

2. Precision TIG Welding

TIG (Tungsten Inert Gas) welding ensures seamless joints, increasing the strength and reliability of the bolts, especially in high-stress applications.

3.Customizable Design

From cylindrical shapes to T-shaped designs, these bolts can be tailored to meet specific industry needs. The customization options include size, threading type, and surface finishes.

4.Applications

These bolts are widely used in industries such as:

- Automotive: Assembly components and machinery.

- Construction: High-load-bearing structures.

- Electronics: Secure and precise installations.

Benefits of Partnering with Us

Machiningfabtech can make customized bolts by various processes like CNC machining, forging, punching,cold forming, and welding fabrication, Machiningfabtech is always seeking the best process to help the customers reduce the cost.

By choosing our "custom bolt services", you gain access to:

- High-quality manufacturing.

- Competitive pricing.

- Reliable delivery schedules.

- Comprehensive after-sales support.

If you are looking for "customized bolts", contact us today for a tailored quote. Let us help you enhance your projects.

How do we save costs for T-shaped bolts?

To save costs on T-shaped bolts, consider the following strategies without compromising on quality or functionality:

1. Optimize Material Selection

Standardize Materials: Use commonly available materials, such as carbon steel or stainless steel, instead of specialty alloys unless required.

Grade Adjustment: Opt for lower-grade materials if high strength or corrosion resistance is not critical for your application.

2. Simplify Design

Reduce Complexity: Minimize non-essential features like intricate grooves or threading unless necessary.

Tolerances: Use standard tolerances instead of tight ones, as tighter tolerances increase machining costs.

Head Design: Choose a simpler T-head design that’s easier to machine or forge.

3. Manufacturing Process Efficiency

Bulk Production: Order in larger quantities to benefit from economies of scale.

Forging Over Machining: Consider hot or cold forging for the head and thread instead of CNC machining, which is more time-consuming and costly.

Thread Rolling: Use thread rolling instead of cutting for stronger threads and lower costs.

4. Supplier Collaboration

Local Sourcing: Work with suppliers in regions with lower manufacturing costs.

Multiple Bids: Get quotes from multiple suppliers to compare pricing and negotiate better terms.

Standardization: Use standard sizes and specifications that suppliers can easily produce.

5. Post-Processing Optimization

Surface Treatment: Use cost-effective coatings like black oxide or zinc plating rather than expensive alternatives unless required.

Batch Processing: Batch similar parts for heat treatment or surface finishing to reduce setup costs.

6. Logistics and Inventory Management

Optimize Shipping: Consolidate shipments to reduce

transportation costs.

JIT Inventory: Use Just-In-Time inventory systems to avoid overstocking and storage expenses.

7. Utilize Automation

Leverage automated processes for high-volume production to minimize labor costs and reduce errors.

By implementing a combination of these strategies, you can achieve significant cost savings on T-shaped bolts while maintaining acceptable performance standards.

Follow Us

Contact

© 2024. All rights reserved.

Privary Policy

Refund Policy